Our technology

LEEMONS introduces a disruptive solar technology that enhances panel efficiency with minimal impact on existing production lines. It leverages a novel electron multiplication mechanism to overcome thermalisation losses and significantly boost energy conversion.

Improved efficiency

What if single-junction solar cells could significantly exceed the theoretical ~30% efficiency limit?

This efficiency gain is being pursued through an advanced strategy that embeds functional nanostructures into the crystalline silicon matrix using advanced ion implantation and finely tuned annealing processes.

Low-Energy Electron Multiplication (LEEM)

The LEEM approach breaks a long-standing axiom in photovoltaics: the notion that each photon can generate at most one electron in the conduction band. The LEEM effect enables the generation of multiple electrons from a single photon with energy only slightly above the silicon band gap.

Key points

Innovation

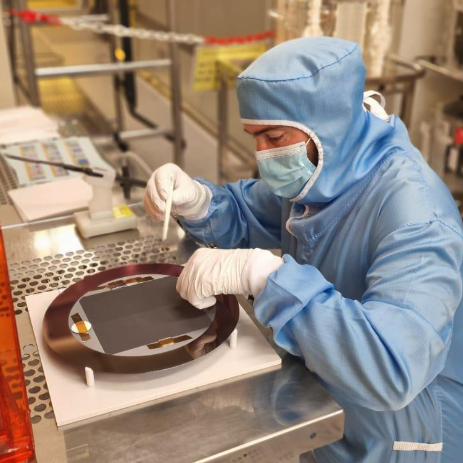

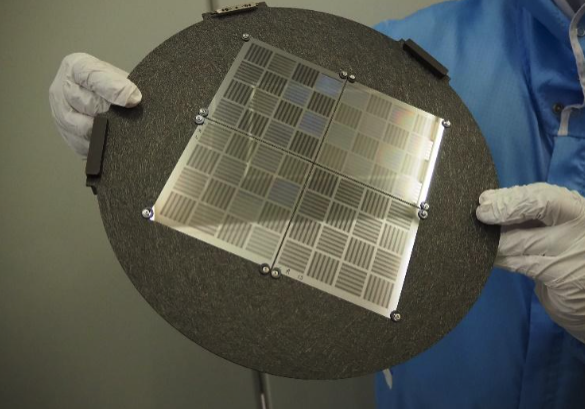

A key aspect of LEEMONS technology involves using ion implantation to form a buried, discontinuous amorphized nanolayer within the crystalline silicon wafer, enhancing electron transport. To enable this, two innovative hard mask approaches are developed: one using Deep Reactive Ion Etching (DRIE) on silicon wafers, and another based on advanced stencil printing techniques.

Industrialisation

LEEMONS brings its breakthrough to the mature photovoltaic sector by adapting existing production lines, avoiding the need for new infrastructure. Using microelectronics-based tools, deployment can be fast and remain cost-effective. This innovation may reduce production costs compared to imported PV cells and support Europe's reindustrialization in the field of solar cell manufacturing.

Sustainability

The approach relies on nanostructuring conventional monocrystalline silicon cells by integrating amorphized silicon layers, without the use of rare earths or toxic materials. It fully aligns with existing sustainability and recycling standards in PV manufacturing. This disruptive advancement supports the EU’s transition to a net-zero emissions economy, while safeguarding biodiversity, natural resources, and environmental integrity.